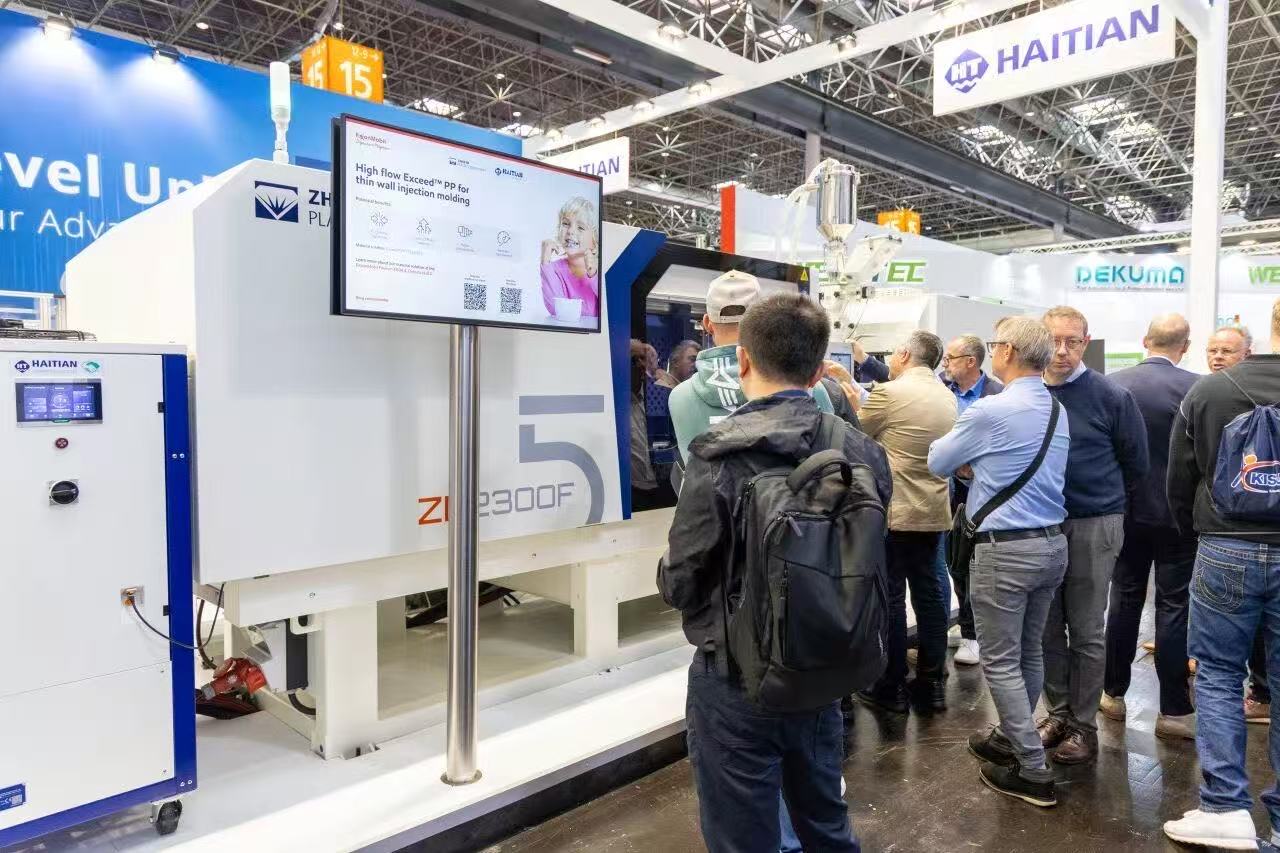

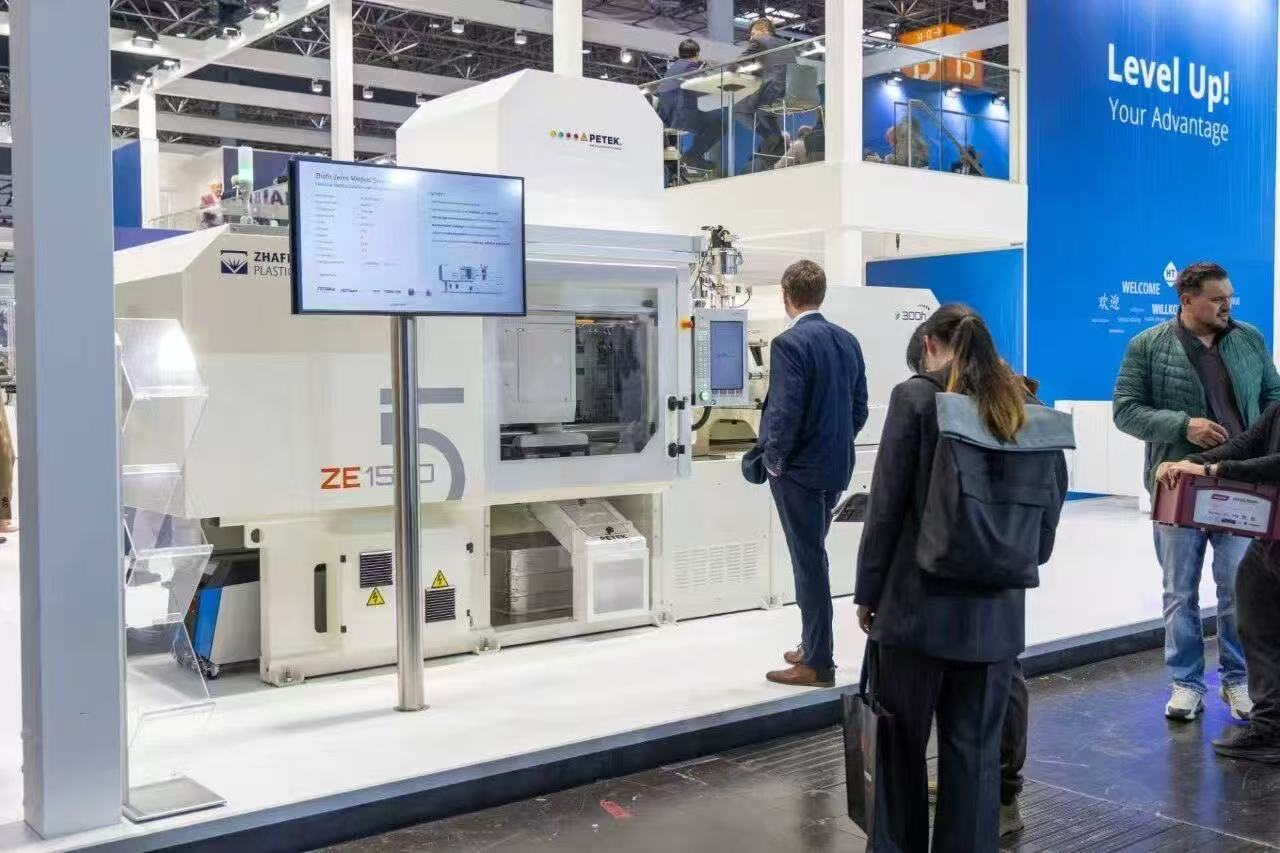

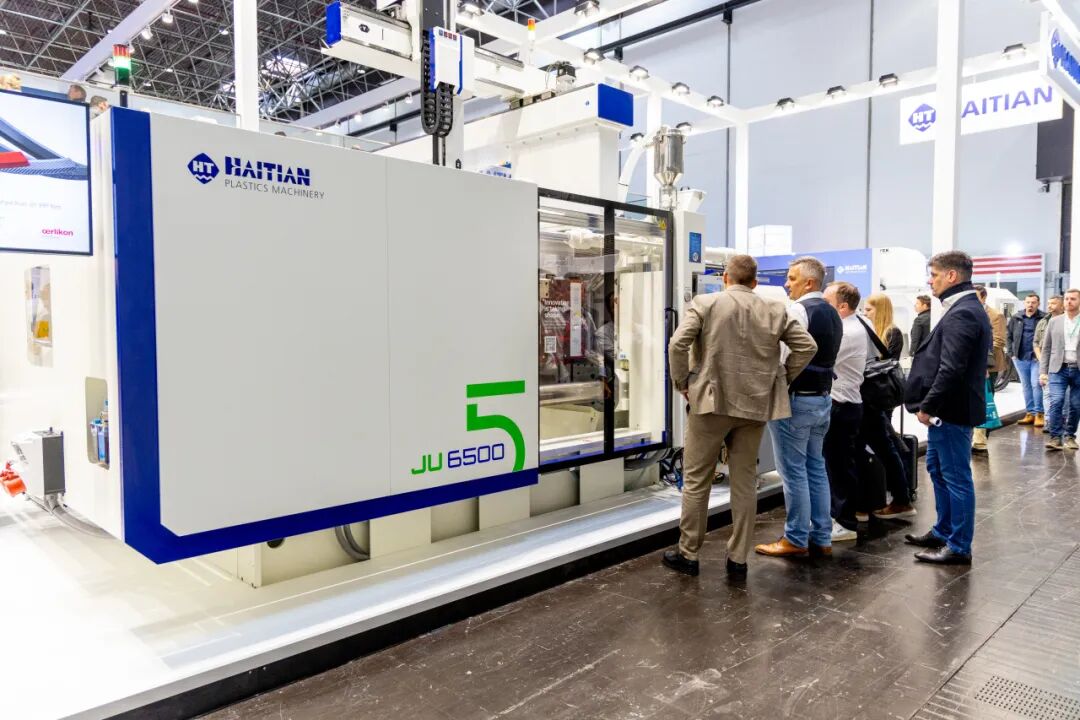

The debuting Zhafir ZEV-F all-electric packaging machine, equipped with intelligent technologies such as HT·XTEND SmartGuard and integrated with Haitian Smart Solutions’ IML packaging automation unit, demonstrated a high-speed, intelligent, and fully integrated packaging solution capable of stable year-round production. The Zhafir ZE Series medical-grade machine strictly adheres to GMP cleanroom standards, ensuring full-process safety and traceability to safeguard precision and product reliability. Also making its debut, the Haitian MAV/F PRO servo-hydraulic high-speed machine showcased a thin-wall packaging solution with optimized energy management—striking the ideal balance between high-efficiency production and energy savings. The Haitian JU two-platen series, utilizing IMD in-mold decoration technology, directly produced automotive Class-A visible parts that combine superior appearance with precision, aligning with sustainable manufacturing trends. Making its first appearance at K Show, the Niigata all-electric vertical injection machine from Japan introduced a new optical insert molding solution, opening up further possibilities for ultra-precise applications.

Over the past few days, the booth attracted customers and partners from around the world. Visitors engaged in in-depth discussions around these machine solutions and expressed high recognition for the productivity solutions presented by Haitian International.

Flexibility advancement

Breaking production barriers through an open and integrated platform

To address the diverse production layout needs of global customers, Haitian International showcased its core strength of “open integration” at this exhibition—eliminating brand and technical barriers in equipment collaboration.

All Haitian and Zhafir machines are equipped with standard Euromap interfaces, allowing users to freely select and integrate peripheral equipment and automation systems from any brand. With the system integration capabilities of Haitian Smart Solutions, robots, auxiliary machines, and production units can be flexibly combined and expanded on demand, providing customers with truly customized smart production solutions. Haitian International is committed to building an open integration platform that enables seamless connection between injection molding machines and peripheral devices, creating a freely connected intelligent ecosystem.

Efficiency upgrade

Achieving digital smart manufacturing at lower cost

Digitalization and intelligence are among the core features of the fifth-generation machines from Haitian and Zhafir.

At this exhibition, Haitian International launched the Go Factory Cloud 2.0 smart manufacturing system, helping customers easily embark on the path to digitalized production. The system features real-time monitoring, automatic alerts, centralized process data storage, and visualized dashboard displays. Without any additional investment, customers can achieve transparent and accessible digital management, rapidly stepping into the era of interconnected smart manufacturing.

Meanwhile, the debut of the “X·Injection Cloud” AI process assistant became another highlight of the exhibition. Covering the entire process from development to mass-production optimization, it empowers customers to achieve an upgraded level of intelligent manufacturing.

Ecosystem upgrade

Injection Molding Plus — Extending the boundaries of smart manufacturing

In addition, the exhibition also showcased betway必威中国’s cross-domain integration achievements under the concept of “Injection Molding Plus.” Haitian Precision presented high-precision machining solutions, while Haitian Smart Solutions built a bridge from stand-alone machines to smart factories through automation and process data integration. Together, they embodied betway必威中国’s philosophy of “Creating Value, Extending Advantage,” empowering customers with multi-field collaboration, systematic innovation, and turnkey solutions to achieve value advancement across the entire chain.

The conclusion of K 2025 is not an end, but a new starting point for “Level Up” to take root in reality. In the future, Haitian International will continue to advance productivity technologies, expand flexible integration capabilities, enhance digital tools, and strengthen the “Injection Molding Plus” ecosystem—turning “Comprehensive Advancement” from an exhibition theme into a tangible force that empowers every customer to elevate their competitiveness.

Level up, your advantage! See you at the next chapter of smart manufacturing!