On July 9, Haitian Indonesia officially opened its Semarang Application Center. Over 50 key local customers and partners gathered to witness this milestone in strengthening regional technical service capabilities.

The newly launched Semarang Application Center integrates mold testing services, a high-turnover spare parts inventory, and ready-stock injection molding machines—offering customers a one-stop solution for immediate testing, verification, and delivery. As a key initiative in Haitian’s Southeast Asia strategy, the center aims to energize Indonesia’s plastics industry with fast response and full lifecycle support.

At the opening event, two flagship machines became the center of attention. The Haitian MA3800H/PRO demonstrated the efficient production of takeaway containers, earning high praise for its stable injection performance and energy-saving design. Meanwhile, the MA1600GII showcased its precision and operational excellence through a dry cycle display. Guests were drawn to the live demonstrations, many stopping to watch and capture the moment with photos.

At the event, Mr. Tao, General Manager of Haitian Indonesia, delivered a speech outlining the company’s development strategy for the Indonesian market. He emphasized that the Semarang Application Center will serve as a key link in leveraging Haitian’s strengths in technology, service, and innovation. With a more professional approach and faster response capabilities, Haitian Indonesia aims to become a vital bridge—connecting with customers, serving the market, and continuously creating value for the local plastics manufacturing industry.

Following that, Mr. Luo Jun, Manager of the Semarang Center, reviewed the development journey of the service site and highlighted the current team’s strengths. The center is now equipped with a professional technical support team and a high-turnover spare parts inventory. It also offers a three-year free maintenance policy for injection molding machines and a two-year free parts replacement policy. In addition, the center will provide customers with professional training in equipment maintenance, servicing, and process optimization.

After the opening ceremony, the Haitian Indonesia team engaged in in-depth discussions with customers on market trends, industry needs, and process optimization. The launch of the Semarang Application Center marks a further step in strengthening Haitian’s localized service network in Indonesia. Haitian remains committed to continuous investment, leveraging technology and service excellence to build an efficient service network across the country—working hand in hand with Indonesian partners to shape the future of the plastics industry.

The post Haitian Semarang Center Opens to Boost Tech Support in Indonesia appeared first on betway必威中国.

]]>Senior Leadership Gather to Witness a New Beginning

On May 16, 2025, betway必威中国 and Haier Smart Home Co., Ltd. (hereinafter referred to as “Haier Smart Home”) officially held a signing ceremony for a global strategic cooperation agreement at the Haier Ecosystem Brand Center. This event marks a new milestone in their 30-year partnership, expanding into a broader global strategic collaboration.

Mr. Zhang Jianfeng, Chairman and President of Haitian Plastics Machinery Group, attended the signing ceremony together with Mr. Ye Jingbo, Assistant President and General Manager of the China Region, Mr. Mao Yucheng, General Manager of the North China Region, Mr. Chen Bing, General Manager of the Qingdao Branch, and Mr. Chen Yilong, Deputy General Manager of the Qingdao Branch. From Haier, the event was graced by Mr. Li Huagang, Senior Vice President of Haier Group and Chairman & President of Haier Smart Home, Mr. Li Yang, Vice President and Global Head of Procurement at Haier Smart Home, Mr. Liu Xiaobo, General Manager of the Washing Appliance Supply Chain, and Ms. Wang Rongmei, General Manager of Indirect Procurement. At the ceremony, Mr. Zhang Jianfeng and Mr. Li Huagang signed the strategic cooperation agreement on behalf of Haitian and Haier respectively, officially launching a new chapter in their partnership.

Powerful Partnership: Focusing on Smart Manufacturing and Customized Services

As leaders in the field of equipment manufacturing and smart home ecosystems, Haitian and Haier will deepen their integration of advanced technologies such as intelligent manufacturing, big data, and artificial intelligence. The partnership aims to explore customized services that meet full-scenario user demands and to jointly build a co-creative and mutually beneficial ecosystem. Haitian will provide Haier with world-class technical support and efficient supply chain services, leveraging its global network to support Haier’s localized smart manufacturing and agile response in overseas markets. Additionally, the two parties will cooperate on talent development, jointly cultivating skilled professionals in intelligent manufacturing to accelerate the implementation of ecosystem capabilities.

Three Decades of Trusted Collaboration,Advancing Global Ecosystem Co-Creation

Since Haier purchased its first Haitian injection molding machine in 1995, the two companies have built a close partnership spanning three decades. To date, Haitian has delivered over 500 high-performance injection molding machines to Haier and has been recognized with multiple honors, including the “Global Partner Award.”Going forward, Haitian will continue to support Haier in building intelligent and connected factories, and in establishing a digitalized and intelligent production system. This upgraded strategic collaboration will further integrate the global resources of both parties and lay a solid foundation for jointly building a “one-stop intelligent manufacturing service chain” in international markets. In the future, Haitian and Haier will deepen their cooperation and explore new paths in intelligent manufacturing and customized services—delivering higher-quality, more efficient experiences to customers around the world.

The post Haitian x Haier | Global Strategic Cooperation appeared first on betway必威中国.

]]>Kejia (Changxing) Mould Base Manufacturing Co., Ltd. (Kejia Mould Base) is a company specializing in the production of die casting mould bases and the sales of mould steel. Established in 1984, the company now employs over 420 people and owns more than 200 CNC machining centers and various processing equipment. Kejia Mould Base has integrated the upstream and downstream production chain, connecting forging, heat treatment, rough machining, and precision machining. It has become a leading large-scale mould base manufacturer in China.

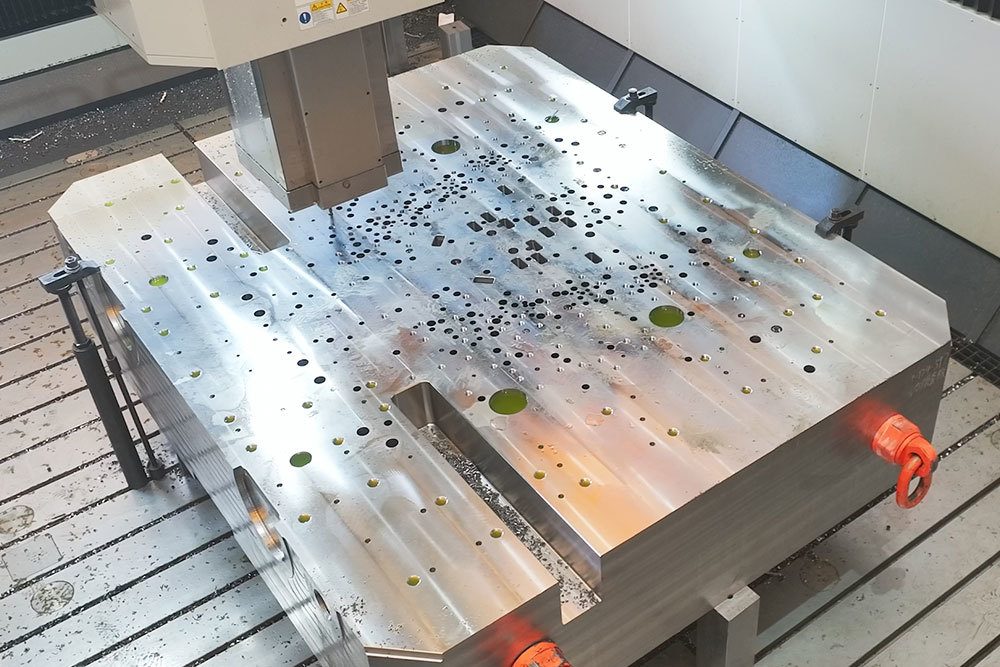

Die casting mould development requires mould base support, as the structure and manufacturing precision of the mould base directly impact the mould’s structure and the precision of forgings. The quality innovation journey between Kejia Mould Base and Haitian Precision began in 2008, with the purchase of the first HTM-1000G, which is still in operation today for rough machining of steel parts.

Kejia Mould Base Deputy Director – Su Jian

Su Jian, the General Manager of Kejia Mould Base, has deep insights into Haitian Precision’s machines. Over the 16 years of cooperation, Haitian Precision has gained his trust with its strong technical advantages, reliable product quality, and efficient processing capabilities. A stable and reliable partner like Haitian Precision has enabled steady business growth. Currently, 20 Haitian Precision machines are hard at work in Kejia’s new Changxing facility, contributing to Kejia’s growing sales performance.

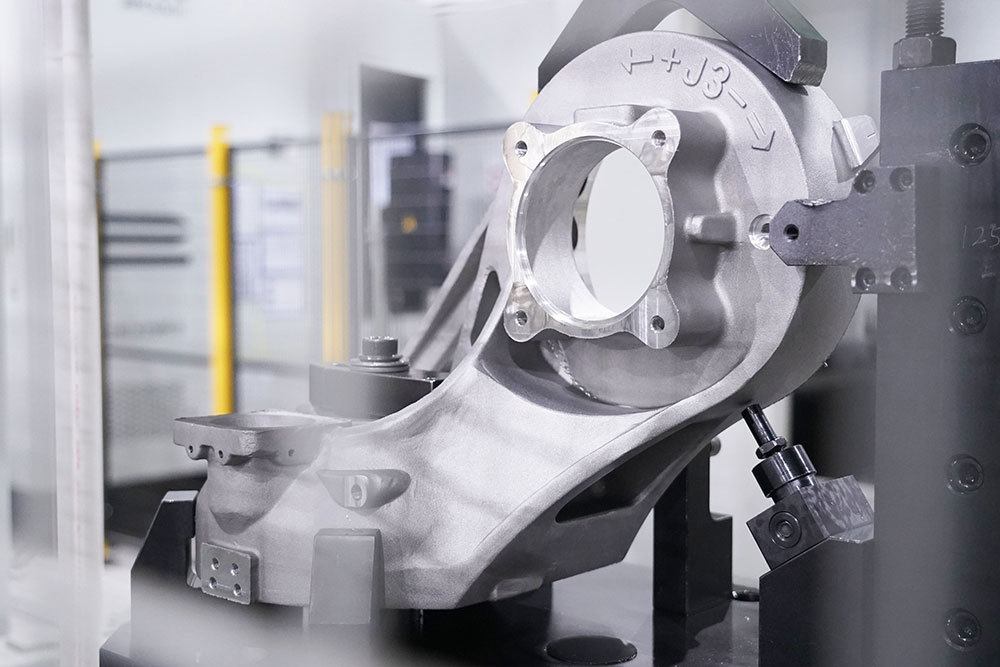

Amid the wave of large-scale die casting, Kejia Mould Base keenly anticipated market trends and was the first to collaborate with a renowned international automotive brand to co-develop the world’s first aluminum alloy die-cast chassis rear axle mould base. This innovation marked a historic breakthrough, reducing the number of components from over 300 parts needing stamping and welding to just three for assembly. Non-standard mould bases have higher commercial value, and this breakthrough also tested the precision and rigidity of Haitian Precision’s equipment.

Haitian Precision’s gantry-type five-face milling center excels in high-speed, high-precision machining of complex surfaces, making it ideal for moulds with large surfaces, multi-angle deep cavities, and automotive body panels. At Kejia Mould Base, Haitian Precision’s equipment is used to manufacture mould bases for new energy vehicle front and rear axles, battery boxes, and other components. The side milling head allows for the processing of five surfaces in one setup, and angled cuts can be completed with a single clamping, achieving excellent precision and high surface smoothness. Additionally, after implementing Haitian Precision’s equipment, processing times have been significantly shortened, delivering impressive efficiency.

Production Manager of Kejia Mould Base Yang Kui

„Haitian Precision’s gantry machines are highly rigidincreasing processing efficiency by 30-40% whenworking with materials with a hardness of HRC50-60. „

Kejia Mould Base’s Changxing facility now has the capacity to produce over 3,000 sets of mould bases annually, including over 300 sets of lightweight integrated structural mould bases for new energy vehicles. With rapid business growth, Kejia Mould Base has increased its investment in digitization by introducing ERP, MES, and OA systems to ensure a complete product supply chain, shorten production cycles, and ensure fast delivery. The company is optimizing its smart manufacturing capabilities and deepening cooperation with Haitian Precision to guarantee efficient and stable processing. Currently, Kejia Mould Base has established long-term partnerships with well-known brands such as XPeng and NIO, and plans to further expand into North American and European markets to enhance the global competitiveness and market share of its large-scale mould bases and integrated die-cast mould bases.

In the mould base industry, Kejia Mould Base has won customers over with its technology and quality. We firmly believe that innovation is the driving force behind industrial progress. Whether in traditional industries or new sectors, Haitian Precision continues to innovate and explore the realm of smart manufacturing, playing a key role in every transformation and upgrade in the manufacturing industry.

The post Innovation for Integrated Transformation appeared first on betway必威中国.

]]>Valeo Group is a French industrial group specializing in the design, development, production, and sale of automotive parts, systems, and modules. As one of the world’s leading automotive parts suppliers, Valeo provides comprehensive solutions to all major car manufacturers globally.

As a key base in northern China, Valeo’s Changchun division is a modern automotive parts manufacturing facility that integrates R&D, production, and sales. It focuses on producing essential components such as automotive air conditioning, engine cooling modules, and active grille shutters. The company demonstrates strong market competitiveness and development potential through its advanced technology and efficient management.

Changchun, the cradle of China’s automotive industry, bears the legacy and ambitions of the country’s automotive manufacturing sector. This land has witnessed the thriving development of China’s automotive industry and fostered the rise of both domestic and international automotive and parts manufacturing companies, creating a complete industrial chain.

Recently, we had the privilege of visiting this iconic automotive city and Valeo’s Changchun division, where we explored the company’s expertise and forward-thinking approach in automotive manufacturing with Equipment Manager Mr. Wei Xuedong.

01 Two-Platen Machines More Space and Higher Efficiency

Haitian Two-platen Machines in Operation

On Valeo’s production line, Haitian two-platen machines play a vital role. With stringent requirements for automotive parts, Valeo not only pursues precision but also values production efficiency. Injection molding machines are crucial to the production process, and Mr. Wei Xuedong’s professional insight and careful approach are evident when selecting equipment. He highlighted the importance of plasticizing screw components and control precision as the core of injection molding machines. Haitian machines have won Valeo’s trust with their outstanding performance and consistent quality.

Inside the workshop, multiple Haitian injection molding machines are operating at full capacity. The two-platen machines, known for their compact design and high production efficiency, maximize productivity in limited spaces. They precisely shape each automotive part, significantly improving production efficiency while maintaining high product quality, embodying Valeo’s commitment to excellence.

02 Multi-componentInjection Molding Machines A Powerful Tool for Precision Manufacturing

Haitian’s Multi-component Injection Molding Solution

Last year, Valeo introduced Haitian’s multi-component injection molding solution, enabling the production of complex, multifunctional automotive parts such as multi-colored, multi-material interior components. This customized solution offers Valeo greater flexibility to meet changing market demands.

Wei shared, “The Haitian equipment we are currently using meets all of our requirements. Its CMK values, in some instances, exceed 3, with an average of about 2.2.” Haitian machines not only meet Valeo’s operational needs but also provide exceptional quality assurance with their high CMK values.

03 Excellence in Service Builds Trust

What impresses Valeo most is Haitian’s after-sales service. When comparing with other brands in the industry, Mr. Wei gave Haitian the highest praise: “What I appreciate most is Haitian’s after-sales team—they are highly efficient, and their service is undoubtedly the best!” Haitian’s team responds quickly and effectively, resolving technical issues and ensuring smooth production. This level of satisfaction is no coincidence; it is the result of Haitian’s ongoing pursuit of quality improvement and service optimization over the years.

As the sun set over the bustling workshop, our visitcame to an end. The collaboration between Haitianand Valeo represents the perfect blend of technologyand customer needs as well as the harmonious resonance ofinnovation and stability.In the ever-evolvingautomotive industry, Haitian injection molding ma.chines have earned Valeo’s trust and support withtheir reliable product quality and excellent after-sales service.

As technology continues to advance and our partner.ship deepens, Haitian and Valeo will jointly usher inautomotive manufacturing, driving progress in theindustry with outstanding products and services.

The post Partnership Elevates Auto Parts Production appeared first on betway必威中国.

]]>Guangdong Blue Sky Plastic Products Co., Ltd. (Blue Sky) was founded in 1988 and is a professional manufacturer engaged in the research and development of plastic household daily necessities, mold manufacturing, injection molding, and sales. The company covers an area of over 67,000 square meters, with modern workshops of more than 100,000 square meters, modern loading and unloading platforms, an ultra-large raw material storage warehouse, and a large group of high-precision injection molding machines, as well as an intelligent unmanned production workshop. The company is committed to technological innovation and brand strategy development. With strong production capabilities and rich industry experience, it has now become a leader in the domestic household daily necessities industry.

02 First Witness ofNew Energy Efficiency and Productivity

As a long-term partner of Haitian, Blue Sky has had full confidence in the quality and technological innovation of Haitian’s products over the years. Therefore, when Haitian launched its fifth-generation technology, Blue Sky was quick to embrace this new technology with a forward-looking vision, opening a new chapter of energy efficiency and productivity.

Now, let’s join Yang Moulu, Assistant to the CEO of Blue Sky, to see how Blue Sky is leveraging these machines to achieve a win-win in production efficiency and environmental benefits.

02 A New BenchmarkThe Fifth-Generation TechnologyLeading Green Benefits

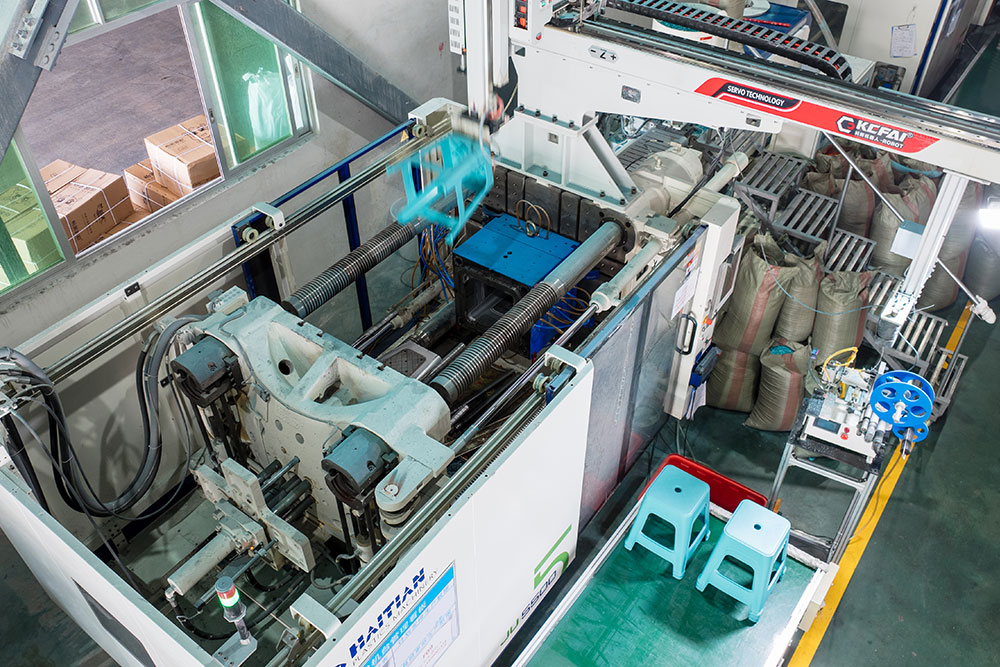

Upon entering Blue Sky’s workshop, 122 Haitian injection molding machines were lined up, working intensely and orderly. Each injection molding machine, with its excellent performance, demonstrates Blue Sky’s relentless pursuit of product quality and production efficiency. Among them, the newly introduced Haitian JU fifth-generation injection molding machines stand out. Under the efficient operation of the JU fifth-generation machines, chairs are precisely formed, smoothly demolded, and produced like flowing water.

After a year of use and precise testing, Yang Moulu from Blue Sky told us, “For a chair weighing 1,300 grams, it used to take 66 seconds to produce with a third-generation machine, but the JU fifth-generation machine can achieve a production cycle of about45 seconds.”

This reduction of 21 seconds significantly improves production efficiency, showcasing the fifth-generation injection molding machine’s precise control over time costs and extreme pursuit, bringing substantial benefits to Blue Sky.

Equally impressive is the excellent energy-saving performance of Haitian’s fifth-generation injection molding machines. With the same screw and clamping force tonnage, strict energy consumption comparison tests show that the fifth-generation machines are 24% more energy-efficient than the third-generation machines. This figure is not only a leap in technology but also a responsibility and contribution to the environment.

03 HT·XTEN DA New Era of Production

In addition to significant efficiency and energy-saving effects, the HT·XTEND equipped on the fifth-generation injection molding machines has also brought unprecedented convenience to Blue Sky. Blue Sky’s frontline technicians can easily capture production data through the extensive intelligent functions with HT·XTEND, enabling fine analysis and scientific optimization, which is crucial for further improving production efficiency and product quality. Not only does this align with the development trends of modern manufacturing, but it also lays a solid foundation for Blue Sky’s long-term development.

Moreover, the fifth-generation injection molding machines from Haitian have also won Blue Sky’s favor with their outstanding stability and dsurability. During long-term operation tests, these machines consistently maintained a high-efficiency and stable working state, providing strong support for Blue Sky’s continuous production.

As one of the first users of Haitian’s fifth-generationinjection molding machines, Blue Sky is activelydemonstrating its relentless pursuit of quality and in-novation. The collaboration has not only brought significant improvements in production efficiency andcost savings to Blue Sky but set a new benchmark forthe entire industry.

Today, Blue Sky has fullyimplemented the use of Hai.tian’s fifth-generation injection molding machinesand has shared its successful experience with theentire industry. Looking ahead, we hope that Haitianand Blue Sky will continue to collaborate, exploringmore possibilities and jointly writing a new greenchapter of sustainable development.

The post New Energy Efficiency: The 5th Generation Leading Green Benefits appeared first on betway必威中国.

]]>In the vast blue ocean of smart manufacturing, Estun Automation, a leader in robotics and automation, continuously drives industrial upgrades with its profound technical expertise and spirit of innovation. As a standout in the industrial machine tool sector, Haitian Precision’s high-precision and highly stable equipment is well recognized in the industry. When Estun met Haitian Precision, a deep collaboration in smart manufacturing began, creating a tale of mutual cooperation and integration.

01 Increasingly Seamless Collaboration

Established in 1993, Nanjing Estun Automation (Estun) adheres to an open, innovative, and striving business philosophy, consistently focusing on independent R&D for core technologies. From core components to motion control, and further to robotics and digital intelligent solutions, Estun remains at the forefront of the industry, providing customers with comprehensive smart manufacturing services. Behind this is Estun’s relentless pursuit of manufacturing equipment and stringent quality control over its products.

Encountered with growing production capacity demands, Estun decided to upgrade its overall smart factory solutions by introducing a more efficient Flexible Manufacturing System (FMS). After extensive research and in-depth discussions, Haitian Precision stood out among numerous domestic and international competitors, securing a strategic partnership with Estun due to the high precision of its machine tools and comprehensive technical support.

As the equipment gradually arrived and was installed and debugged, the teams from both sides worked closely to continuously optimize production processes, ensuring each step achieved its best state. Since its launch at the beginning of the year, Haitian Precision’s FMS has been running stably, with production steadily increasing, proving the correctness of Estun’s choice.

02 A Dual Leap in Efficiency and Quality

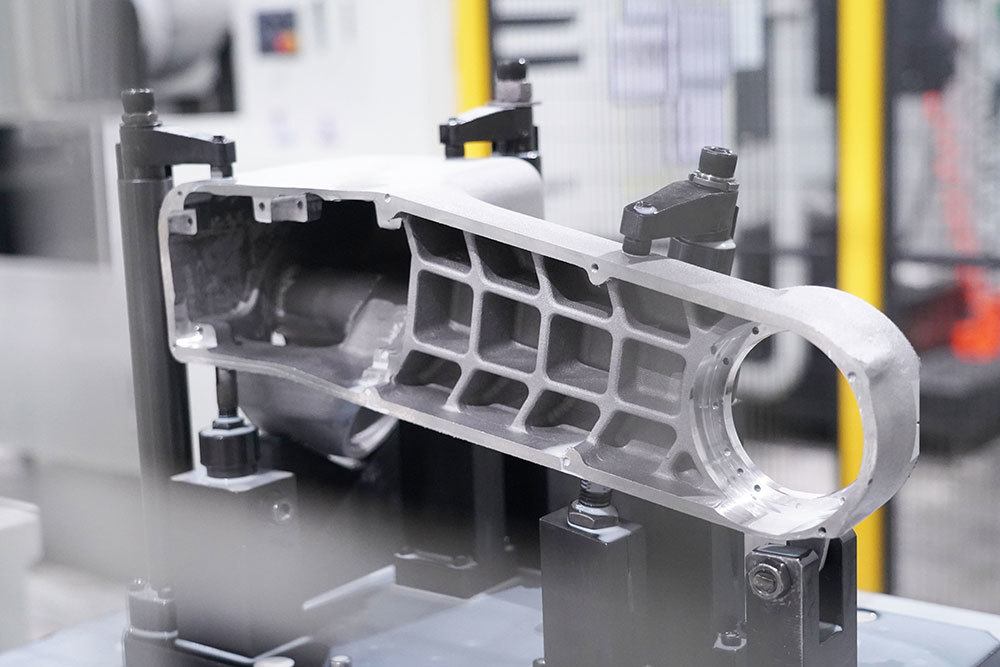

Haitian Precision’s FMS focuses on the precision machining of motor housings, drive casings, robot bases, and arm castings, bringing significant efficiency improvements to Estun. The introduction of FMS allows for zero-changeover and zero-switching when processing various complex robot components, significantly enhancing equipment utilization. At the same time, Haitian Precision’s high-precision machine tools ensure that the machining accuracy meets or even exceeds expectations, laying a solid foundation for Estun’s product quality.

Haitian Precision’s FMS has effectively improved Estun’s production and processing model. In terms of manpower, what once required one person per machine now only needs one to two people to manage six machine tools in continuous operation, greatly increasing processing efficiency. Additionally, the flexible line’s built-in tool breakage monitoring function can automatically switch tools using sister tools, protecting tool life and reducing downtime. The multiple sets of process programming within a single machine can automatically select processing based on the loaded workpieces, offering distinct advantages over traditional gantry lines or robots in the production of small batches of diverse products. The high-precision horizontal machining centers from Haitian Precision also demonstrate outstanding performance, running stably and meeting both high-load cutting and high-speed processing needs, fully maximizing efficiency.

Assistant to the President of Estun: Li Wenlong

“FMS has further enhanced production operatingrates, reaching a high level of 90%-95%. The preci-sion is also spot-on, with daily part accuracy within10 microns, fully meeting production requirements.”

03 Comprehensive Support and Assurance

Estun highly praises Haitian Precision’s machineries, believing that it matches or even surpasses foreign brands in performance. Haitian Precision’s technical support and after-sales service have provided Estun with unprecedented convenience and peace of mind. The technical personnel at Haitian Precision are not only professional and responsible but also proactively analyze and eliminate potential risks after resolving issues, preparing preemptive plans to ensure the continuous and stable operation of the production line.

Haitian Precision understands the importance of after-sales service, from equipment installation and debugging to daily maintenance. Their technical application personnel are always by their side, ensuring the equipment is always in its best state. Additionally, Haitian Precision has provided customized services tailored to Estun’s production needs for robot part machining, further improving production efficiency and machining accuracy.

Chief Engineer of Estun: Zhang Haicheng

“Haitian Precision has given Estun strong supportin technology and services, and their guidance hasbeen of great help to our equipment staff.”

As emerging industries continue to seek both “new” in “quality”, Estun and Haitian Precision have formed complementary advantages in the industrial chain, bringing about mutual understanding and synergy. Intelligent matching allows the machine tool’s performance to be maximized, while the machine tool ensures efficient and stable production of parts. High-end CNC machine tools and smart equipment are setting a new benchmark for the industry, opening up new boundaries in smart manufacturing. The story of Estun and Haitian Precision in this manufacturing revolution continues…

The post Innovative, Boundless Smart Manufacturing appeared first on betway必威中国.

]]>